Embossing

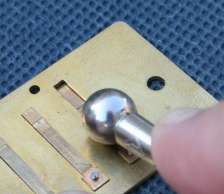

A very effective modification is the narrowing of the slot (embossing). The reed slot is narrowed by pressing a round metal object along the sides of the slot, causing them to bend inward slightly.

%3Cobject%20width%3D%22640%22%20height%3D%22385%22%3E%3Cparam%20name%3D%22movie%22%20value%3D%22https%3A//www.youtube.com/v/8U-7mbqaXQw%26hl%3Den_US%26fs%3D1%26rel%3D0%26color1%3D0x3a3a3a%26color2%3D0x999999%22%3E%3C/param%3E%3Cparam%20name%3D%22allowFullScreen%22%20value%3D%22true%22%3E%3C/param%3E%3Cparam%20name%3D%22allowscriptaccess%22%20value%3D%22always%22%3E%3C/param%3E%3Cembed%20src%3D%22https%3A//www.youtube.com/v/8U-7mbqaXQw%26hl%3Den_US%26fs%3D1%26rel%3D0%26color1%3D0x3a3a3a%26color2%3D0x999999%22%20type%3D%22application/x-shockwave-flash%22%20allowscriptaccess%3D%22always%22%20allowfullscreen%3D%22true%22%20width%3D%22640%22%20height%3D%22385%22%3E%3C/embed%3E%3C/object%3E

A popular tool to use for this is the back of a tuning fork. The round ball at the end of the fork is placed on top of the reed and is moved along the reed while gently pressing down. This is delicate work and a few passes are usually required.

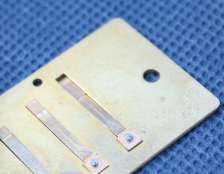

Hold the plates up against the light to check the clearance between reed and slot.

If the reed gets stuck, check for rough edges either on the reed or the slot edges.

If the slot becomes too narrow it can easily be pushed back with the tip of a small screwdriver.

%3Cobject%20width%3D%22640%22%20height%3D%22385%22%3E%3Cparam%20name%3D%22movie%22%20value%3D%22https%3A//www.youtube.com/v/IiUVnn5qivA%26hl%3Den_US%26fs%3D1%26rel%3D0%26color1%3D0x3a3a3a%26color2%3D0x999999%22%3E%3C/param%3E%3Cparam%20name%3D%22allowFullScreen%22%20value%3D%22true%22%3E%3C/param%3E%3Cparam%20name%3D%22allowscriptaccess%22%20value%3D%22always%22%3E%3C/param%3E%3Cembed%20src%3D%22https%3A//www.youtube.com/v/IiUVnn5qivA%26hl%3Den_US%26fs%3D1%26rel%3D0%26color1%3D0x3a3a3a%26color2%3D0x999999%22%20type%3D%22application/x-shockwave-flash%22%20allowscriptaccess%3D%22always%22%20allowfullscreen%3D%22true%22%20width%3D%22640%22%20height%3D%22385%22%3E%3C/embed%3E%3C/object%3E

Narrowing the slot increases the overall responsiveness of the reed and reduces leakage when the reed is choked. The reduced leakage has a very big impact on overblow playing.

before embossing (click to enlarge)

before embossing (click to enlarge)

after embossing (click to enlarge)

after embossing (click to enlarge)

before embossing (click to enlarge)

before embossing (click to enlarge) after embossing (click to enlarge)

after embossing (click to enlarge)

As far as burrs do you get that happening after you emboss? I saw someone else emboss and they said it's best to use like mineral oil to help avoid it. Have you heard of that? Also how do you decide when you've embossed enough? Do you do it until you only get a sliver of light around the reed or is there some measure you aim for? Sorry for all the questions!

I haven't really pursued tip scooping much so far because i really don't have a tiny file that's suitable. I have very small needle file type things but i think they're still a bit too large for doing it. The one i saw you doing it with in the video looked really ultra thin. Oh i meant to say; on your advice i bought one of those tuning forks with the ball on the end. Makes it so much easier to control the embossing. That was a cool tip.

Thanks.

Gary

Sorry for all the questions but getting my harps set up for overblows and overdraws is kinda an obsession with me!

Cheers Tinus.

Gary

I tried to emboss a session steel reed plates, but the effect is neglect. I believe it is because of the steel being much harder to reshape than brass. how do you work with this kind of reed plates?

I have been playing and blowing on the harmonica for seventy one years .I am glad to see the word choking on over blow .com . now days it is called cross harp. Deford Bailey used it many years ago on the Grand old Opry. I have learned a lot from you keep up the good work. Digger

which sequence should the harp modification be?

is embossing to arcing to gapping right?

can the tip scooping and corner rounding be ignored?

and by gently does that mean dont exert pressure while embossing?

I do the other side of the reed plate too. you?

2. yes you can, try making an indentation along the top of the slot about 5 micron from the edge of the slot. That should push the edge inward.

If the reed gets stuck make sure it is aligned properly, check for tuning burs and if after that it is still stuck gently push back the slot edge with a small screwdriver.

1. Will this effect overblows?

2. Can you emboss the slot end, to close the gap and what should you do if the reed gets stuck through over embossing?

Thanks in advance.

Kieron

When embossing, how do you avoid scraping the reed itself when you are running the rounded tool back and forth along the slot. It seems impossible to emboss more than 20% of a slot without scraping the middle of a reed in doing it... I see in the picture above, it seems your reeds have a scrape down the middle as well. Is there a way to avoid this/is it necessary to?

Thanks,

Sam

What is the right order to implement these steps?

Corner Rounding, Embossing, Waxing, Arcing and Gapping - What order do you usually do?

I forgot to add my address in the threadfollower; it's sorted now :-)